Babban Gudun Babban Ingantacciyar PE Bututu Extrusion Line

Bayani

Ana amfani da injin bututun Hdpe don samar da bututun ban ruwa na noma, bututun magudanar ruwa, bututun iskar gas, bututun samar da ruwa, bututun magudanar ruwa da dai sauransu.

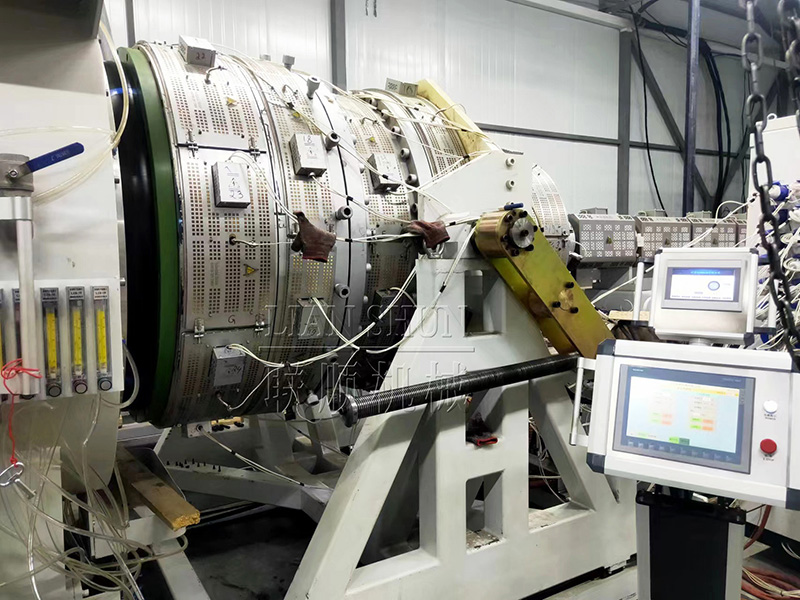

PE bututu extrusion line kunshi bututu extruder, bututu ya mutu, calibration raka'a, sanyaya tank, ja-kashe, abun yanka, stacker / coiler da duk peripherals. Hdpe bututun injin yana samar da bututu tare da diamita daga 20 zuwa 1600mm.

The bututu yana da wasu kyau kwarai fasali irin su dumama resistant, tsufa resistant, high inji ƙarfi, muhalli danniya fasa resistant, mai kyau creep resistant, da dai sauransu Hdpe bututu extrusion inji an tsara tare da high dace extruder da sanye take da reducer wanda yake shi ne babban gudun da low amo, gravimetric dosing naúrar da ultrasonic kauri nuna alama za a iya harhada bisa ga abokin ciniki ta bukatar zuwa hawan da bututu.

Juya key bayani za a iya bayar, kamar Laser printer crusher, shredder, ruwa chiller, iska kwampreso da dai sauransu don cimma high-sa da atomatik tube samar.

Tsarin Tsari

Raw material+ Master Batches → Mixing → Vacuum Feeder → Filastik Hopper Drier → Single dunƙule extruder → Co-extruder for launi kirtani & Multi Layers → Mold da calibrator → Vacuum Calibration Tank → Fesa Cooling Water Tank → Haul-off Machine → yankan inji → Stacker (Winding Machine)

Features da Abvantbuwan amfãni

Injin bututu na 1.Hdpe yana haɓaka ta hanyarmu dangane da fasahar ci gaba na Turai da ƙwarewar R & D na injin filastik na shekaru masu yawa, ƙirar ci gaba, tsari mai ma'ana, babban aminci, babban digiri na atomatik.

2. Hdpe bututu extruder tare da musamman ganga ciyar tsarin iya fi mayar inganta extrusion iya aiki.

3. Madaidaicin kula da zafin jiki, mai kyau filastik, aikin barga.

4. Hdpe bututu na'ura yana ɗaukar tsarin kula da PLC, fahimtar aiki tare da aiki da kai.

5. Mutum-kwamfuta yana da sauƙi don aiki, dacewa kuma abin dogara.

6. Nau'in kwandon karkace da lattice sun mutu don zaɓi.

7. Canza wasu sassan layi kuma na iya gane haɗin gwiwa mai Layer biyu da Multi-Layer.

8. Canza wasu sassan layi kuma na iya samar da PP, PPR bututu.

Cikakkun bayanai

Single Screw Extruder

Dangane da 33: 1 L / D rabo don dunƙule zane, mun ɓullo da 38: 1 L / D rabo. Idan aka kwatanta da 33: 1 rabo, 38: 1 rabo yana da amfani na 100% plasticization, ƙara yawan ƙarfin fitarwa ta hanyar 30%, rage yawan amfani da wutar lantarki har zuwa 30% kuma ya kai kusan aikin extrusion na layi.

Simens Touch Screen da PLC

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

Karkataccen Tsarin Ganga

Sashen ciyar da ganga yana amfani da tsarin karkace, don tabbatar da ciyarwar kayan cikin kwanciyar hankali da kuma ƙara ƙarfin ciyarwa.

Zane na Musamman na Screw

An tsara dunƙule tare da tsari na musamman, don tabbatar da ingantaccen filastik da haɗuwa. Abubuwan da ba a narkewa ba ba za su iya wuce wannan ɓangaren dunƙule ba.

Tushen yumbu mai sanyaya iska

Injin yumbu yana tabbatar da tsawon rayuwar aiki. Wannan ƙirar ita ce haɓaka wurin da mahaɗar ke hulɗa da iska. Don samun sakamako mafi kyawun sanyaya iska.

Akwatin Gear Mai inganci

Za'a tabbatar da daidaiton gear 5-6 da ƙaramar amo ƙasa da 75dB. Karamin tsari amma tare da babban juyi.

Extrusion Die Head

Extrusion mutu shugaban shafi karkace tsarin, kowane abu kwarara tashar an sanya a ko'ina. Kowane tashoshi yana bayan maganin zafi da gogewar madubi don tabbatar da kwararar kayan cikin lafiya. Tsarin kai na mutuƙar ƙarami ne kuma yana ba da kwanciyar hankali, koyaushe daga 19 zuwa 20Mpa. A karkashin wannan matsa lamba, ingancin bututu yana da kyau kuma yana da tasiri kaɗan akan ƙarfin fitarwa. Zai iya samar da Layer guda ɗaya ko bututu mai yawa.

Motsi Na'urar Die Head

Don babban girman shugaban mutu, na'urar motsi na iya matsar da mutun gaba da baya, kuma daidaita tsayin shugaban mutu. Aiki yana da sauri da sauƙi.

Die Head Rotary Device

Don babban girman shugaban mutuwa tare da na'urar jujjuyawa, shugaban mutun na iya juyawa ta digiri 90. Lokacin canza daji, mandrel, shugaban mutun zai juya digiri 90. Za a iya amfani da crane don ɗagawa da canza daji da mandrel. Wannan hanya ta dace sosai.

Na'urar Hana Zafi

Ana kara wannan na'urar a kan mutun don samar da babban bututu mai kauri. Don shayar da zafi a cikin bututu da bututun sanyaya cikin bango. Za'a iya amfani da ƙura mai zafi don bushe albarkatun ƙasa.

Na'urar sanyaya don Core

Lokacin samar da bututu mai girman diamita da kauri na bango, za mu yi amfani da ruwa mai sanyaya ko mai tare da mai sanyaya mai sanyaya don kwantar da ainihin mutun don guje wa dumama da tabbatar da ingancin kayan abu mai kyau.

Matsakaici Calibration Tank

Ana amfani da tanki na Vacuum Calibration don siffa da sanyaya bututu, don isa daidaitaccen girman bututu. Muna amfani da tsarin ɗaki biyu. Gidan farko yana cikin ɗan gajeren tsayi, don tabbatar da sanyaya mai ƙarfi sosai da aikin injin. Kamar yadda aka sanya calibrator a gaban ɗakin farko kuma siffar bututu an kafa shi ne ta hanyar calibrator, wannan ƙira na iya tabbatar da sauri da mafi kyawun tsari da sanyaya bututu.

Sanyi mai ƙarfi don Calibrator

Tare da tsarin sanyaya na musamman don calibrator, wanda zai iya samun sakamako mafi kyau na sanyaya don bututu kuma tabbatar da babban gudun. Hakanan tare da bututun feshi mai inganci don samun ingantaccen sakamako mai sanyaya kuma ba sauƙin toshewa ta hanyar ƙazanta ba.

Kyakkyawan Taimako don Bututu

Don babban girman bututu, kowane girman yana da nasa farantin tallafi na semicircular. Wannan tsarin zai iya kiyaye zagaye na bututu sosai.

Shiru

Muna sanya shiru a kan injin daidaita bawul don rage hayaniya lokacin da iska ta shigo cikin tankin injin.

Valve Taimakon Matsi

Don kare bututun ruwa. Lokacin da injin injin ya kai iyakar iyaka, bawul ɗin zai buɗe ta atomatik don rage matakin injin don guje wa karyewar tanki. Za a iya daidaita iyakancewar digiri.

Bututun Madauki Biyu

Kowane madauki tare da tsarin tace ruwa, don samar da ruwan sanyi mai tsabta a cikin tanki. Madauki biyu kuma yana tabbatar da ci gaba da samar da ruwan sanyaya a cikin tanki.

Ruwa, Gas Separator

Don raba ruwan ruwan gas. Gas ya gaji daga sama. Ruwa yana gudana cikin ƙasa.

Cikakken Kulawar Ruwa ta atomatik

Tare da sarrafa zafin jiki na inji don samun daidaito da kwanciyar hankali na zafin ruwa.

Dukan tsarin shigar da ruwa da tsarin fitarwa ana sarrafa cikakken atomatik, barga da abin dogaro.

Na'urar magudanar ruwa ta tsakiya

Duk magudanar ruwa daga tanki mai ɗorewa an haɗa su kuma an haɗa su cikin bututun bakin ruwa guda ɗaya. Sai kawai haɗa bututun da aka haɗa zuwa magudanar ruwa na waje, don sauƙaƙe aiki da sauri.

Fesa Tankin Ruwa Mai Sanyi

Ana amfani da tanki mai sanyaya don ƙara kwantar da bututu.

Na'urar Dake Bututu

Wannan na'urar na iya daidaita zagaye na bututu lokacin da bututun ya fito daga tanki.

Tankin Ruwa Tace

Tare da tacewa a cikin tankin ruwa, don guje wa duk wani babban ƙazanta lokacin da ruwan waje ya shigo.

Ingancin Fesa Nozzle

Ingantattun nozzles na fesa suna da kyakkyawan sakamako mai sanyaya kuma ba sauƙin toshe shi ta hanyar ƙazanta.

Na'urar Gyara Taimakon Bututu

Taimako tare da aikin daidaitawa don tallafawa bututu tare da diamita daban-daban.

Na'urar Tallafawa Bututu

Musamman ana amfani dashi lokacin samar da bututu tare da babban diamita da kauri na bango. Wannan na'urar za ta ba da ƙarin tallafi ga manyan bututu.

Kashe mashin

Injin cirewa yana ba da isassun ƙarfin jan bututu don jan bututu a tsaye. Dangane da nau'ikan bututu daban-daban da kauri, kamfaninmu zai keɓance saurin juzu'i, adadin ƙwanƙwasa, tsayin gogayya mai tasiri. Don tabbatar da saurin fitar da bututun wasa da saurin samar da bututu, haka nan kuma guje wa nakasar bututu yayin gutsi.

Rarrabe Motar Gogayya

Kowanne kambori yana da nasa na'urar motsa jiki, idan motar jaggo ɗaya ta daina aiki, sauran injinan suna iya aiki. Za a iya zaɓar motar servo don samun ƙarfin juzu'i mai girma, mafi tsayayyen saurin gogayya da faffadan saurin juzu'i.

Na'urar Daidaita Claw

Ana haɗa dukkan ƙuƙuka da juna, lokacin daidaita matsayi na ƙwanƙwasa don cire bututu a cikin nau'i daban-daban, duk ƙusoshin za su motsa tare. Wannan zai sa aiki da sauri da sauƙi.

Zane na Abokin Amfani

Tare da Siemens hard ware da software na abokantaka mai amfani wanda kamfaninmu ya tsara. Yi aiki tare tare da extruder, sauƙaƙe aiki da sauri. Hakanan abokin ciniki zai iya zaɓar wasu ƙwanƙwasa don aiki don cire ƙananan bututu.

Ikon Matsalolin Iska daban

Kowace katsewa tare da nasa ikon sarrafa iska, mafi daidaito, aiki yana da sauƙi.

. Babban ja da ƙarfi ba tare da rasa siffar bututu ba

. An sanye shi da 2, 3, 4, 6, 8,10 ko 12 caterpillars bisa ga aikace-aikacen.

. Motar Servo don samar da ingantaccen juzu'i da gudu

. Matsayin motsa jiki na ƙananan caterpillars

. Sauƙaƙe aiki

. Kariyar gabaɗaya ta rufe don iyakar aminci

. Masu isar da sarƙoƙi tare da sandunan roba na musamman akan sarƙoƙi waɗanda ba su da alama akan bututu.

. Aiki tare tare da extruder dunƙule gudun ba da damar barga samarwa yayin canza samar da gudun

Injin yankan bututu

Filastik mai yankan bututu wanda kuma ake kira injin yankan bututu wanda Siemens PLC ke sarrafawa, yana aiki tare da kashe naúrar don samun yankan daidai. Abokin ciniki zai iya saita tsawon bututun da suke son yanke. Multi-feed-a ayyuka domin cimma daya yankan tsari (kare ruwan wukake da saws, hana daga ruwa da saws makale ga lokacin farin ciki bututu da yanke fuskar bututu ne santsi).

Na'urar Maƙarƙashiya ta Duniya

Aiwatar da na'urar clamping na duniya don girman bututu daban-daban, babu buƙatar canza na'urar matsawa lokacin da girman bututu ya canza.

Gani da Ruwa Mai Musanya

Wasu masu yankan suna sanye take da zato da ruwa. Saw da yankan ruwa ana iya musanya su don girman bututu daban-daban. Hakanan, saw da ruwa na iya aiki tare don buƙatu na musamman.

Daidaita Tsayin Tsayi

Tare da na'urar daidaita wutar lantarki don na'urar matsawa. Aiki cikin sauri da sauƙi. Tare da iyakance iyaka don tabbatar da aminci.

. Aiki tare ta atomatik tare da saurin extrusion

. Planetary sanye take da faifai da milling abun yanka don yanke da chamfering

. Chip-free sanye take da faifai ruwa don tabbatar da santsi yankan saman ba tare da wani kura

. Taba allon kula da panel

. Dukkan motsi suna motsa jiki kuma ana sarrafa su ta hanyar sarrafawa

. Toshe bututu tare da amfani da dunƙulewar duniya don aiki cikin sauƙi

. Ƙananan bukatun bukatun

. Rufe gabaɗaya kuma amintaccen inji don iyakar aminci

Stacker

Don tallafawa da sauke bututu. Tsawon stacker za a iya musamman.

Kariyar saman bututu

Tare da abin nadi, don kare saman bututu lokacin motsi bututu.

Daidaita Tsayin Tsayi

Tare da na'urar daidaitawa mai sauƙi don daidaita tsayin tsakiya don girman bututu daban-daban.

Coiler

Don murɗa bututu zuwa abin nadi, mai sauƙin ajiya da sufuri. Yawancin lokaci ana amfani da bututu da ke ƙasa da girman 110mm. Yi tasha ɗaya da tasha biyu don zaɓi.

Amfani da servo motor

Za a iya zaɓar motar servo don ƙaurawar bututu da jujjuyawar bututu, mafi inganci kuma mafi kyawun matsewar bututu.

Bayanan Fasaha

| Tsawon diamita (mm) | Extruder model | Max. Iya aiki (kg/h) | Max. saurin layi (m/min) | Ƙarfin wutar lantarki (KW) |

| 20-63 | SJ65/33 | 220 | 12 | 55 |

| 20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15×2 | 110 |

| 20-110 | SJ65/33 | 220 | 12 | 55 |

| 20-110 | SJ60/38 | 460 | 30 | 110 |

| 20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ 90/38 SJ 90/38 | 1,900 | 0.6 | 280 280 |