Sauran layin extrusion bututu don siyarwa

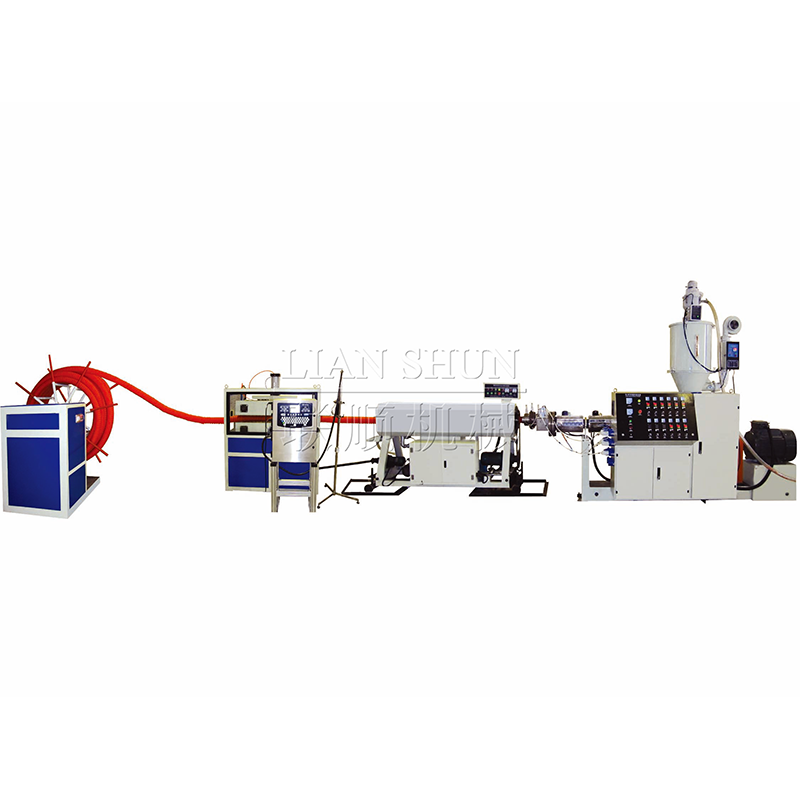

Karfe waya kwarangwal ƙarfafa filastik hada bututu inji

Karfe waya kwarangwal ƙarfafa filastik hada bututu inji ne yadu amfani a masana'antu, birnin samar da ruwa, gas, sinadarai da noma, da dai sauransu. Wannan layin iya amfani da karfi karfe waya, gilashin fiber bunch da PET don samar da karfi hada roba bututu. Yana kuma iya samar da polyethylene ruwa ko gas bututu ma. Manufa iri-iri ne don adana jari. Bututun yana da fa'ida na babban matsin lamba, ƙarancin kayan da ake buƙata da ƙarancin ƙima, tec. An yi amfani da ma'auni kuma an aiwatar da shi a cikin shekara ta 2004. An kammala ƙa'idodin aikin injiniya daidai da kayan aiki. Masana'antu, tallace-tallace da haɓakawa sun kasance mataki-mataki-mataki kan hanyar ci gaban masana'antu. Ya zama babban samfurin bututu masu haɗaka.

Kwanan Fasaha

| Samfura | Rage Bututu (mm) | Gudun layi (m/min) | Jimlar Ƙarfin Shigarwa (kw |

| LSSW160 | 中50-φ160 | 0.5-1.5 | 200 |

| LSSW250 | φ75-φ250 | 0.6-2 | 250 |

| LSSW400 | φ110- φ400 | 0.4-1.6 | 500 |

| LSSW630 | φ250- φ630 | 0.4-1.2 | 600 |

| LSSW800 | φ315-φ800 | 0.2-0.7 | 850 |

| Girman Bututu | HDPE Solid Pipe | Karfe waya kwarangwal ƙarfafa filastik hada bututu | ||

| Kauri (mm) | Nauyi (kg/m) | Kauri (mm) | Nauyi (kg/m) | |

| φ200 | 11.9 | 7.05 | 7.5 | 4.74 |

| φ500 | 29.7 | 43.80 | 15.5 | 25.48 |

| φ630 | 37.4 | 69.40 | 23.5 | 40.73 |

| φ800 | 47.4 | 112.00 | 30.0 | 75.39 |

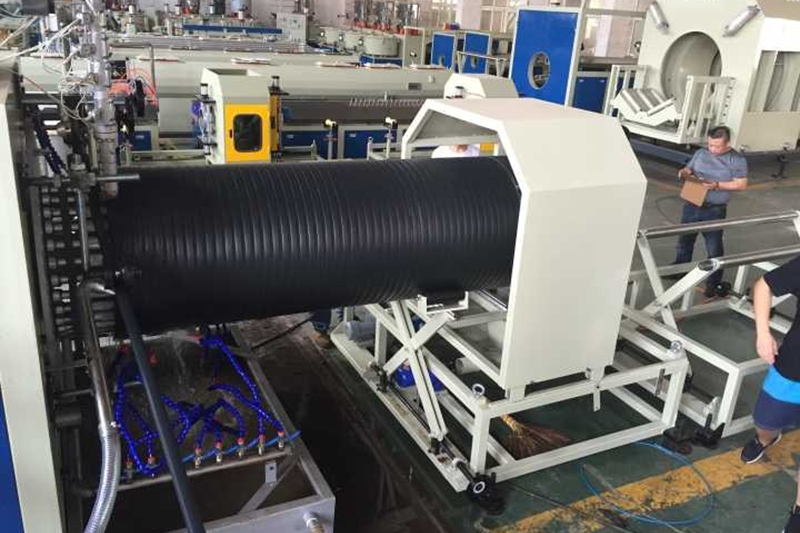

HDPE m bango Winding bututu inji

HDPE m bango winding bututu inji ana amfani da su yin bututu amfani da ruwa magudanun ruwa da najasa a da yawa filayen, kamar gundumomi yi, mazauna gundumomi, manyan tituna da gadoji, da dai sauransu.

Babban bututu mai jujjuya bango ana amfani da shi don tsarin najasa, daidai da bututun bango biyu. Idan aka kwatanta da bututu mai katanga biyu, yana da fa'idodi na ƙarancin saka hannun jari na inji da diamita mafi girma.

Mu PE m winding bututu extrusion line iya aiwatar da dama iri abu, ciki har da HDPE, PP, da dai sauransu, size daga m 200mm zuwa 3200mm tare da guda Layer ko Multi-Layer.

Canza wasu sassa na iya samar da nau'i daban-daban na bututu ko bayanin martaba don samar da nau'ikan bututun karkace daban-daban.

◆Na farko extruder yana samar da bututu rectangular zuwa na'ura mai jujjuyawar iska, na biyu kuma yana samar da sandar filastik, sannan ana danna sandar filastik akan bututun rectangular sannan ya fito waje da cikin bututun yana da kyau da kyau.

◆Yana rungumi karkace mutu shugaban da biyu extruder caji, gane karkace juyawa forming.

◆Tsarin sarrafa kwamfuta na PLC na ci gaba yana ba da sauƙin aiki. Yana da tsayayye kuma abin dogaro.

◆Tare da daban-daban zane na profile tube zai iya samar da bututu na dfrerent zobe stfness cewa audapt todiferet yanayi da felds.

◆High efficiency guda dunƙule extruder (ta amfani da gramule abu) da makamashi-ceton twin screwextruder (amfani da foda ko granule abu forchoice.

◆Canjin wasu sassa kuma na iya samar da bututu mai karkata daga murabba'in ƙarfe.

◆ Cikakken kewayon ƙayyadaddun bayanai, kewayon bututu: ID200mm -ID3200om

Cikakkun bayanai

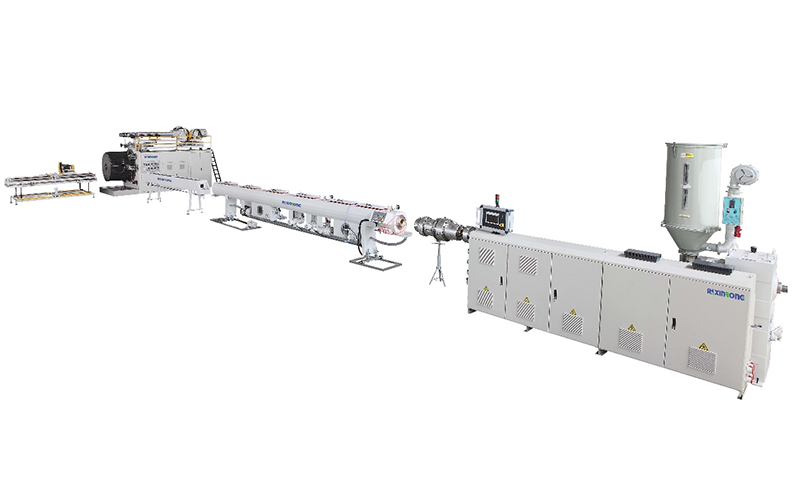

Single Screw Extruder

Dangane da 33: 1 L / D rabo don dunƙule zane, mun ɓullo da 38: 1 L / D rabo. Idan aka kwatanta da 33: 1 rabo, 38: 1 rabo yana da amfani na 100% plasticization, ƙara yawan ƙarfin fitarwa ta hanyar 30%, rage yawan amfani da wutar lantarki har zuwa 30% kuma ya kai kusan aikin extrusion na layi.

Simens Touch Screen da PLC

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

Karkataccen Tsarin Ganga

Sashen ciyar da ganga yana amfani da tsarin karkace, don tabbatar da ciyarwar kayan cikin kwanciyar hankali da kuma ƙara ƙarfin ciyarwa.

Zane na Musamman na Screw

An tsara dunƙule tare da tsari na musamman, don tabbatar da ingantaccen filastik da haɗuwa. Abubuwan da ba a narkewa ba ba za su iya wuce wannan ɓangaren dunƙule ba.

Tushen yumbu mai sanyaya iska

Injin yumbu yana tabbatar da tsawon rayuwar aiki. Wannan ƙirar ita ce haɓaka wurin da mahaɗar ke hulɗa da iska. Don samun sakamako mafi kyawun sanyaya iska.

Akwatin Gear Mai inganci

Za'a tabbatar da daidaiton gear 5-6 da ƙaramar amo ƙasa da 75dB. Karamin tsari amma tare da babban juyi.

Injin iska

Ana amfani da injin iska don iskar bututu mai murabba'i da haɗa su tare don samar da bututu mai karkace. Yana da daidaitacce don samar da daban-daban karkace bututu masu girma dabam, kuma winding mala'ika ne daidaitacce ga square bututu a daban-daban nisa. Tare da ingantaccen sanyaya ruwa.

Glue Extruder

Tare da manne extruder don sanyawa a saman injin iska. Mai extruder na iya motsawa ta kowace hanya: gaba da baya, sama da ƙasa, hagu da dama. Sauƙi don aiki.

Cikakken tsarin daidaitawa

Cikakken saitin tsarin daidaitawa don yin bututun murabba'in nau'in karkace bututu mai sauƙi da kwanciyar hankali.

Gear Drive

Yi amfani da tuƙi na gear, na'ura mai jujjuyawa tana aiki mafi tsayayye, daidaito da inganci.

Siemens PLC girma

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

Mai yanka

Cutter da Siemens PLC ke sarrafawa tare da cikakken tsarin yankan atomatik, wanda zai iya tsara tsayin yanke.

Madaidaicin Jagoran Rail

Aiwatar da layin dogo na jagora, yankan trolly zai motsa tare da layin jagora. Yankan tsari barga da yankan tsawon daidai.

Mai tara ƙura na masana'antu

Tare da mai tara ƙura na masana'antu mai ƙarfi don zaɓi don ɗaukar ƙura.

Stacker

Don tallafawa bututu, tare da abin nadi na goyan bayan roba, abin nadi zai juya tare da bututu.

Roller motor

Don bututu mai girman girman girman, yi amfani da mota don fitar da abin nadi mai jujjuyawa tare da bututu.

Daidaita Tsayin Tsayi

Don bututu mai girman girman girman, yi amfani da mota don daidaita tsayin tsakiya, sauƙi da sauri.

Bayanan Fasaha

| Samfura | Rage Bututu (mm) | Ƙarfin fitarwa (kg/h) | Jimlar ƙarfi (kw) | |

| ID(min) | OD (max) | |||

| ZKCR800 | 200 | 800 | 100-200 | 165 |

| ZKCR1200 | 400 | 1200 | 150-400 | 195 |

| ZKCR1800 | 800 | 1800 | 300-500 | 320 |

| ZKCR2600 | 1600 | 2600 | 550-650 | 400 |

| ZKCR3200 | 2000 | 3200 | 600-1000 | 550 |

PE carbon karkace karfafa bututu extrusion line

| MISALI | SJ90/30 | SJ65/30 |

| PIPE DIAMETER | 50-200 | 20-125 |

| CALIBATE UNIT | SGZL-200 | Saukewa: SGZL-125 |

| MAGANAR KASHE | SLQ-200 | SLQ-200 |

| MASHIN SAKA | SQ-200 | SQ-200 |

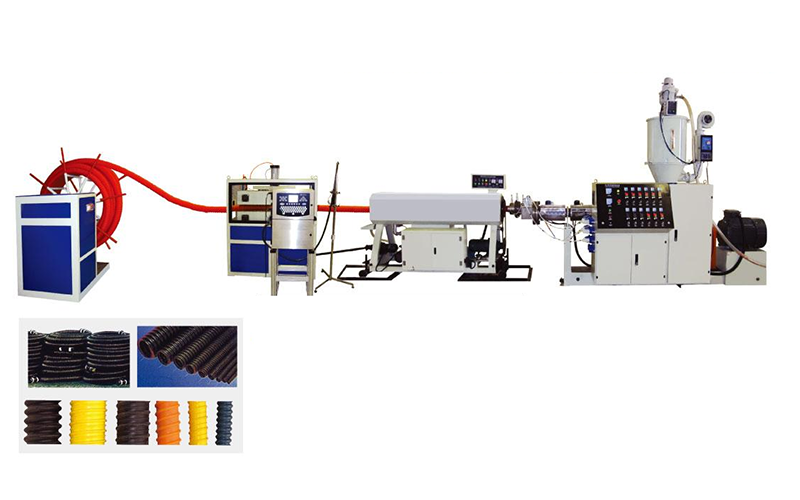

PVC karkace tiyo extrusion line

| Samfura | SJ45 | SJ65 |

| Extruder | SJ45/28 | SJ65/28 |

| Tsawon Dlameter (mm) | φ12-φ50 | φ63-φ200 |

| Fitowa (kg/h) | 20-40 | 40-75 |

| Wutar Wuta (kw) | 35 | 50 |

PVC fiber ƙarfafa tiyo extrusion line

| Extruder | diamita bututu | Iyawa | Wutar da aka shigar | Matsakaicin amfani da makamashi | girman |

| SJ-45×30 | <6-25mm | 35-65kg/h | 39,9kw | 27.5kw | 1.2*3*1.4 |

| SJ-65×30 | <8-38mm | 40-80kg/h | 66,3kw | 39.78kw | 1.3*4*5 |

| extruder | Naúrar cirewa | Braider | Injin sanyaya | Tankin bushewa | iska |

| 2 saiti | 2 saiti | 1 saiti | 2 saiti | 1 saiti | 1 saiti |

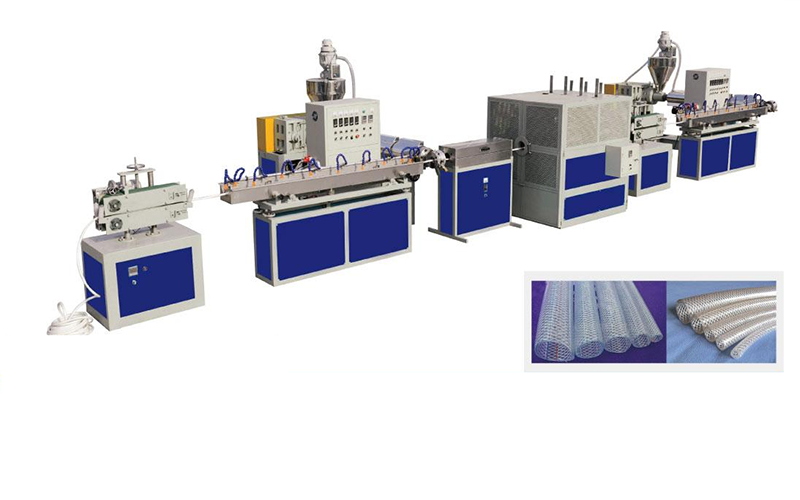

PVC karfe karfafa tiyo extrusion line

| Samfura | SJ45 | SJ65 | SJ90 | SJ120 |

| Extruder | SJ45/30 | SJ65/30 | SJ90/30 | Saukewa: SJ120/30 |

| Tsawon Dlameter (mm) | φ12- φ25 | φ20-φ50 | φ50-φ110 | φ75-φ150 |

| Fitowa (kg/h) | 20-40 | 40-75 | 70-130 | 100-150 |

| Wutar Wuta (kw) | 30 | 40 | 50 | 75 |