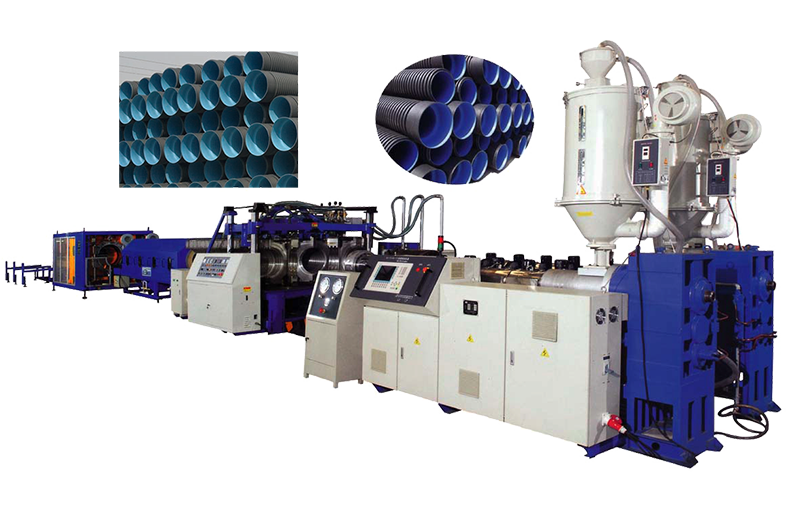

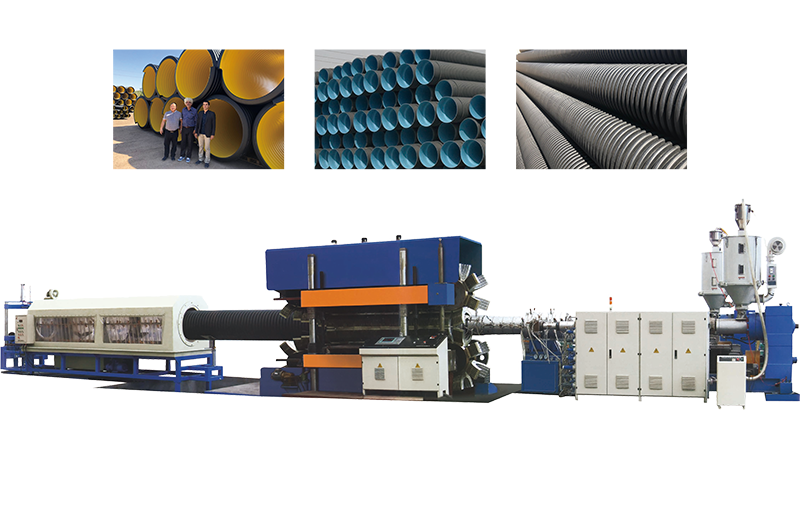

Babban Gudun PE PP (PVC) Layin Fitar Bututu Mai Rarraba

Bayani

Ana amfani da injin bututun filastik don kera bututun filastik, waɗanda galibi ana amfani da su a cikin magudanar ruwa na birane, tsarin najasa, ayyukan manyan tituna, ayyukan ban ruwa na filayen noma, kuma ana iya amfani da su a cikin ayyukan jigilar ruwa na ma'adinan ma'adinai, tare da aikace-aikace masu yawa. Corrugated bututu yin inji yana da abũbuwan amfãni daga high fitarwa, barga extrusion da babban mataki na aiki da kai. Ana iya tsara extruder bisa ga yanayi na musamman na kayan mai amfani, kamar PE PP ko PVC. PE PP mai bangon bangon bangon bangon bango biyu yana amfani da sabon nau'in babban inganci guda / twin dunƙule extruder. Injin bututun da aka lalatar da PVC yana amfani da babban tagwaye mai lebur ko madaidaicin tagwayen extruder. Tare da Layer guda ɗaya da yadudduka biyu don zaɓi. Don yin ɓangarorin bango biyu, akwai nau'ikan guda biyu.kwance bango biyu corrugated bututu extrusion linekumatsaye biyu bango corrugated bututu extrusion line.

Tsarin Tsari

Raw material → Mixing → Vacuum Feeder → Filastik Hopper Drier → Extruder → Extrusion Mold → Samar da Motsi → Ruwan sanyaya Samfurin Na'ura → Fasa Tankin Ruwa → Yanke Inji → Stacker

Features da Abvantbuwan amfãni

1. HDPE rungumi dabi'ar sabon nau'in high-inganci guda / twin dunƙule extruder, da kuma PVC rungumi dabi'ar babban lebur tagwaye ko conical tagwaye extruder. Big conical twin-dunƙule extruder ko a layi daya twin-dunƙule extruder iya gane kyau kwarai plasticization a low zazzabi da kuma barga extrusion.

2. Module sanyaya Hanyar da aka tilasta ruwa sanyaya, wanda ƙwarai inganta sanyaya gudun module, don cimma high-gudun samar.

3. The corrugated bututu line kuma ake kira biyu bango corrugated bututu inji line iya gane kan-line flaring don tabbatar da cewa daban-daban kaddarorin na kafa bututu sun hadu da ka'idoji.

4. Shigo da rabo-daidaita bawul daidaita kafa matsa lamba barga da kuma abin dogara.

5. Horizontal type corrugator

6. Aiki plateform ne uku-girma daidaitacce.

7. Tsarin kariya ta atomatik yana farawa kuma mai aiki yana dawowa lokacin da aka kashe wuta.

8. Tashar man shafawa ta atomatik

9. Mold tubalan an yi su ne na musamman aluminum gami da siffofi haske nauyi, high ƙarfi, mai kyau lalacewa resistant, kananan co-m co-m na thermal fadada.

.

11. Na'urar yankan bututun da aka yi amfani da shi yana da fa'idodi na babban madaidaici kuma babu ƙura.

12. Cikakken layi yana ɗaukar tsarin kula da micro-kwamfuta na PLC wanda zai iya gani yana nuna yanayin zafi da matsa lamba, samar da sauri, ƙararrawa kuskure kuma yana da damar ajiya na tsari na asali.

Cikakkun bayanai

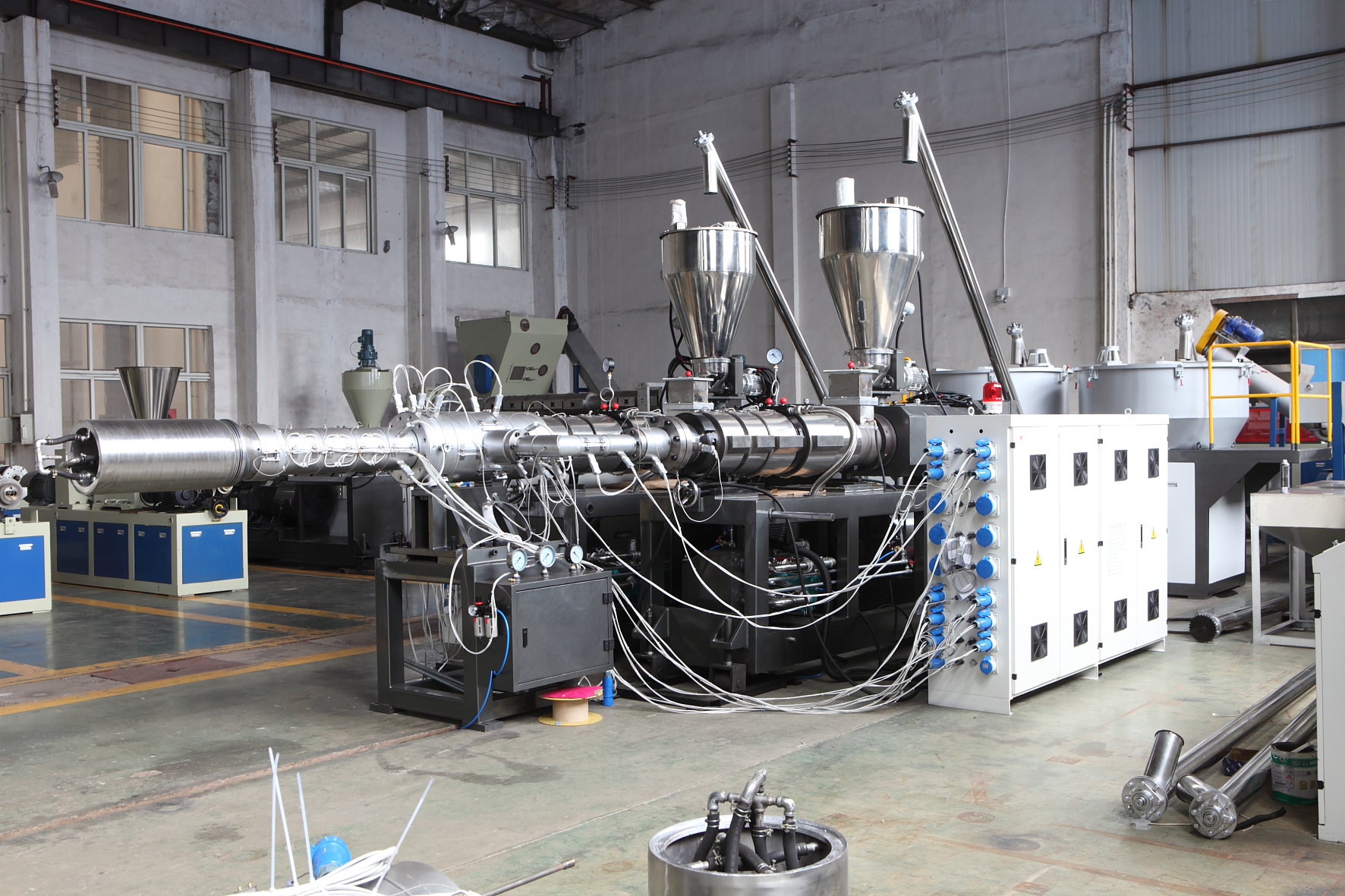

Single Screw Extruder don PE/PP

Dangane da 33: 1 L / D rabo don dunƙule zane, mun ɓullo da 38: 1 L / D rabo. Idan aka kwatanta da 33: 1 rabo, 38: 1 rabo yana da amfani na 100% plasticization, ƙara yawan ƙarfin fitarwa ta hanyar 30%, rage yawan amfani da wutar lantarki har zuwa 30% kuma ya kai kusan aikin extrusion na layi. Ɗauki rabon L/D 38:1 dunƙule don kayan budurwa da L/D 33:1 dunƙule don kayan da aka sake fa'ida.

Simens Touch Screen da PLC

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

Karkataccen Tsarin Ganga

Sashen ciyar da ganga yana amfani da tsarin karkace, don tabbatar da ciyarwar kayan cikin kwanciyar hankali da kuma ƙara ƙarfin ciyarwa.

Zane na Musamman na Screw

An tsara dunƙule tare da tsari na musamman, don tabbatar da ingantaccen filastik da haɗuwa. Abubuwan da ba a narkewa ba ba za su iya wuce wannan ɓangaren dunƙule ba.

Tushen yumbu mai sanyaya iska

Injin yumbu yana tabbatar da tsawon rayuwar aiki. Wannan ƙirar ita ce haɓaka wurin da mahaɗar ke hulɗa da iska. Don samun sakamako mafi kyawun sanyaya iska.

Akwatin Gear Mai inganci

Za'a tabbatar da daidaiton gear 5-6 da ƙaramar amo ƙasa da 75dB. Karamin tsari amma tare da babban juyi.

Conical Twin Screw Extruder don PVC

Dukansu conical twin dunƙule extruder da a layi daya twin dunƙule extruder za a iya amfani da su samar da PVC. Tare da sabuwar fasaha, don rage ƙarfi da tabbatar da iya aiki. Dangane da dabara daban-daban, muna samar da ƙirar dunƙule daban-daban don tabbatar da tasirin filastik mai kyau da babban ƙarfin aiki.

Extrusion Mold

Dukansu na waje da Layer na ciki suna extruded a cikin mutun kai. Kowane tashar kwararar abu a cikin mutun an sanya shi daidai. Kowane tashoshi yana bayan maganin zafi da gogewar madubi don tabbatar da kwararar kayan cikin lafiya. Har ila yau, mutuwar kai yana samar da iska mai matsewa tsakanin sassan biyu. Ana amfani da hannun riga don sanyaya Layer na ciki don samar da bututu mai santsi da lebur a ciki. Ruwan matsi yana gudana a cikin hannun riga don samun tasirin sanyaya mai kyau. An ƙirƙiri Vacuum akan saman hannun hannun riga lokacin samar da babban bututu mai diamita, tabbatar da zagayen bututun ciki.

Samar da Mold

CNC machining yana tabbatar da ma'auni daidai. Jirgin iska mai iska da tashar sanyaya ruwa tare da babban ɓangaren giciye yana tabbatar da kwanciyar hankali, inganci, da ingantaccen aikin samarwa. Kayan na'urar yana da ƙarfin ƙarfe na aluminum mai ƙarfi, tare da haɓakar haɓakar thermal, babban ƙarfi, da juriya mai girma. Tsarin Module yana ɗaukar tsarin simintin matsi mai mahimmanci, tare da nau'in nau'i mai yawa da kwanciyar hankali mafi girma. Jiyya na cikin gida na ƙirar yana inganta ƙarfi da taurin tsarin, wanda ya fi dacewa da cikakkiyar samuwar ripples. A mold rungumi dabi'ar CNC machining don tabbatar da daidaito da kuma santsi aiki.

Na'ura mai sanyaya ruwa

Ana amfani da na'ura mai sanyaya ruwa don sanyawa da motsa gyare-gyaren gyare-gyare, an ƙirƙiri injin don shayar da Layer na waje zuwa cikin ƙwanƙwasa don samar da siffar corrugate. Ta hanyar motsawar gyaggyarawa, ana kuma fitar da bututu daga corrugator.

Tsarin Lubrication Na atomatik

Sa mai ta atomatik ga kayan aikin don yin gyare-gyaren gyare-gyaren da ke tafiya cikin sauƙi.

Rigar Gear Rack

Gear tara ana sanya a saman corrugated mold. Duk akwatunan kaya suna bayan nitriding da dumama magani, tsayin daka na juriya.

Tsarin Gyaran Sama

Daidaita firam na sama ta hanyar lantarki don girman nau'in ƙulla daban-daban. Tare da ginshiƙai huɗu, tabbatar da daidaito da daidaito daidai.

Tsarin daidaitawa na tashin hankali

Don daidaita tsananin motsin ƙirƙira, sanya mold yana motsawa cikin sauƙi.

Daidaitaccen Valve

Don sarrafa iska mafi kwanciyar hankali da daidaito, don samar da kyakkyawan bututu da siffar soket.

Tsarin Sanyaya Mold

Tare da tsarin sanyaya ruwa da tsarin sanyaya iska, don samun kyakkyawan sakamako mai sanyaya, mai kyau da saurin bututun kafa.

Ƙarfin Ajiyayyen UPS

Lokacin da gazawar wuta, UPS madadin ikon ikon zai samar da wuta ga corrugator don fitar da bututu daga calibration hannun riga. Don gujewa bututun da ke makale a hannun rigar daidaitawa bayan sanyaya bututu da raguwa.

Fesa Tankin Ruwa Mai Sanyi

Ana amfani da tanki mai sanyaya don ƙara kwantar da bututu.

Haul-off na taimako

Tare da kashe na'ura mai taimako, kuma na'urar jan hankali tana da sassauƙa. Don kara ja bututu.

Ingancin Fesa Nozzle

Ingantattun nozzles na fesa suna da kyakkyawan sakamako mai sanyaya kuma ba sauƙin toshe shi ta hanyar ƙazanta.

Tankin Ruwa Tace

Tare da tacewa a cikin tankin ruwa, don guje wa duk wani babban ƙazanta lokacin da ruwan waje ya shigo.

Corrugated bututu sabon inji

Na'urar yankan bututun da aka yi da katako yana da inganci kuma babu ƙura.

Na'urar clamping Aluminum

Aiwatar da na'urar clamping aluminum don girman bututu daban-daban. Kowane girman tare da na'urar clamping na kansa, babu buƙatar canza tsayin tsakiya na tsakiya lokacin da girman bututu daban-daban.

Tsarin aiki tare

Motoci da inverter ne ke tafiyar da tashar yanke. Yayin aiwatar da yankan, tashar yanke tana tafiya tare da corrugator don guje wa gurɓacewar bututu.

Yankan Wuka Biyu

Tare da yankan wukake guda biyu tare, don tabbatar da an yanke ƙarshen ɓangaren soket.

Stacker

Don tallafawa da sauke bututu. Tsawon stacker za a iya musamman.

Don tallafawa da sauke bututu. Tsawon stacker za a iya musamman.

Domin matsar da bututu mai laushi a kan stacker, muna shafa bakin karfe gabaɗaya akan saman stacker.

Don murɗa bututu zuwa abin nadi, mai sauƙin ajiya da sufuri. Yawancin lokaci ana amfani da bututu da ke ƙasa da girman 110mm. Yi tasha ɗaya da tasha biyu don zaɓi.

Bayanan Fasaha

| Samfura | Girman bututu (mm) | Extruder | Fitowa (kg/h) | Gudun (m/min) | Jimlar ƙarfi (KW) | Mold (biyu) | Tsarin sanyaya |

| SGB250 | 90-250 | Saukewa: SJ65SJ75 | 300 | 1-4 | 150 | 48 | Sanyaya iska da sanyaya ruwa |

| SGB500 | 200-500 | Saukewa: SJ75SJ90 | 600 | 1-4 | 200 | 40 | Sanyaya iska da sanyaya ruwa |