Farashin injin pelletizer PE PP

Bayani

Injin pelletizer na filastik shine tsarin juya robobi zuwa granules. A cikin aiki, ana narkar da polymer zuwa zobe na igiyoyi waɗanda ke gudana ta hanyar mutuwa ta annular a cikin ɗakin yanke ambaliya da ruwa mai sarrafawa. Shugaban yankan da ke juyawa a cikin rafin ruwa yana yanke igiyoyin polymer zuwa pellets, waɗanda nan da nan ana fitar da su daga ɗakin yanke.

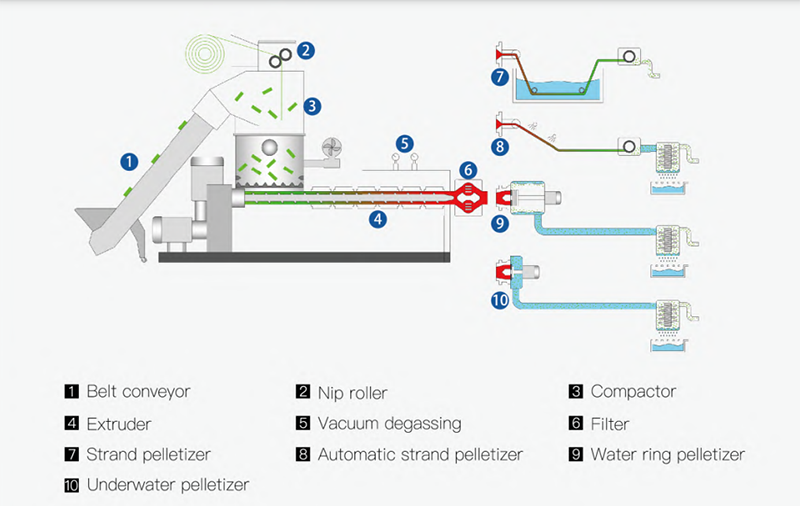

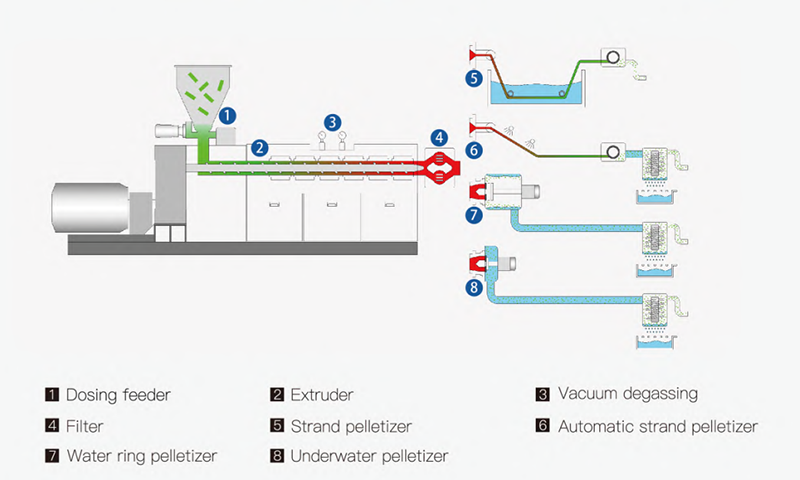

Filastik pelletizing shuka za a iya musamman a matsayin guda (daya kawai extrusion inji) da kuma biyu mataki tsari (daya main extrusion inji da daya karami sakandare extrusion inji).

"Yanke mai zafi" ruwan zobe mai mutuƙar pelletizing fuska da kuma "Cold Cut" hanyoyin pelleting suna samuwa dangane da abin da kuke so.

Narke pelletizing (yanke mai zafi): Narkar da ke fitowa daga mutuwa wanda kusan nan da nan a yanke shi zuwa cikin pellet waɗanda ruwa ko iskar gas ke fitarwa da sanyaya su;

Strand pelletizing (yanke sanyi): Narkewar da ke fitowa daga kan mutun yana juyewa zuwa igiyoyi waɗanda aka yanke su cikin pellets bayan sanyaya da ƙarfi.

Za mu iya kera muku injin pelletizer mai kyau tare da farashin injin pelletizer mai kyau.

Cikakkun bayanai

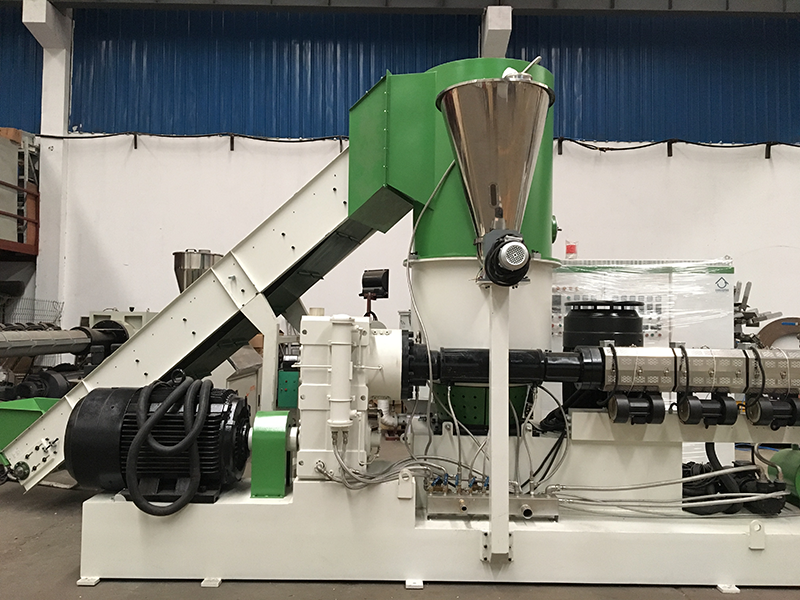

Rukunin Compactor

Haɗin manyan igiyoyin jujjuyawar saurin gudu da tsayayyen ruwan wukake suna saurin saurin haɗawa da sarrafa kayan cikin screws.

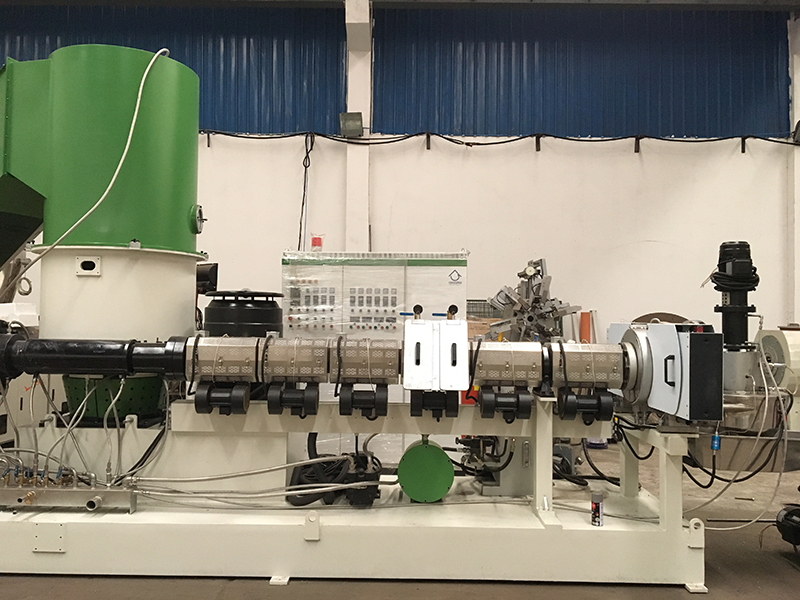

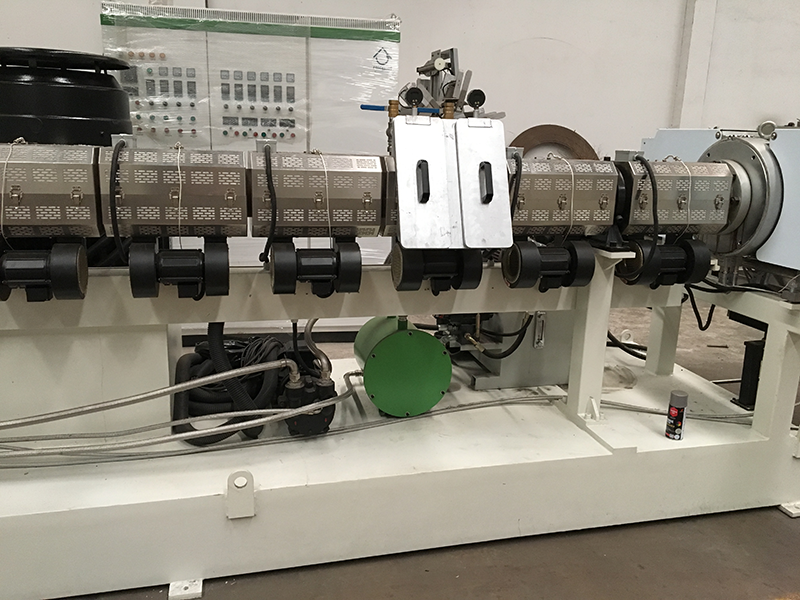

Ƙungiyar Extruder

Ƙwararren dunƙule guda ɗaya da aka yi amfani da shi don narkar da kayan da aka riga aka haɗa a hankali.

Za a narkar da tarkacen filastik da kyau, a sanya su a cikin extruder.

Babban ingantaccen ganga da dunƙule da aka yi amfani da shi don extruder tare da kyakkyawan sakamako na filastik da ƙarfin fitarwa, ɗaukar babban abin da zai iya jurewa don tabbatar da rayuwar sabis na sau 1.5 na al'ada.

Naúrar ragewa

Tare da tsarin tsaftacewa na yanki guda biyu, yawancin masu canzawa za a iya cire su da kyau, musamman ma fim mai nauyi da kayan aiki tare da wasu abubuwan ruwa.

Tace

Nau'in farantin karfe, nau'in pistion da nau'in tacewa ta atomatik, zaɓi daban-daban bisa ga abubuwan ƙazanta a cikin abu da al'adar abokin ciniki.

Fitar nau'in farantin karfe yana da tsada kuma mai sauƙin aiki wanda galibi ana amfani dashi don thermoplastic na yau da kullun kamar yadda aka saba

maganin tacewa.

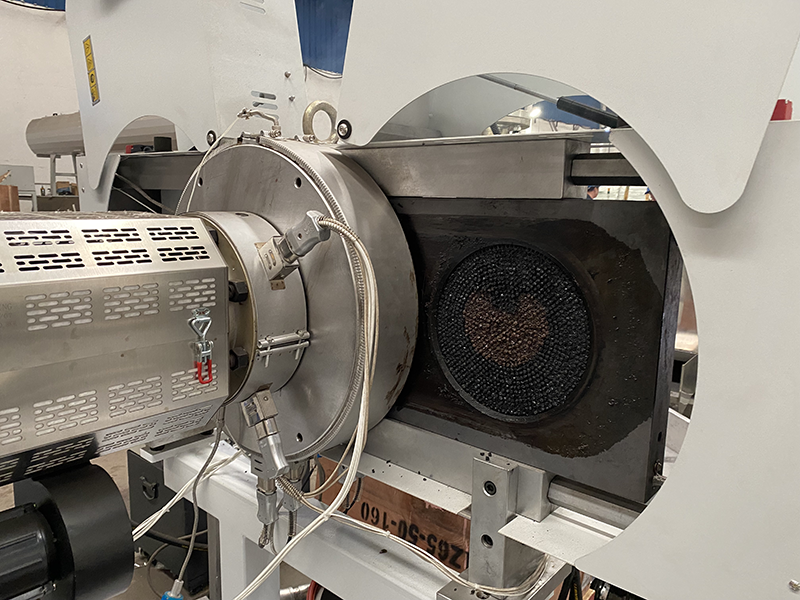

Ruwan zobe pelletizer

Yanke gudun pelletizer da PLC ke sarrafa ta atomatik bisa ga matsi na mutun kai, wanda zai iya cimma daidaitaccen girman pellet ɗin fitarwa.

Wuraren pelletizer suna taɓa faranti ta atomatik ta tsarin huhu, tabbatar da ruwan wukake

tuntuɓar farantin mutu daidai, mai sauƙin aiki da ƙauracewa abrasion.

Bayanan Fasaha

| Nau'in | KCP80 | KCP100 | KCP120 | KCP140 | KCP160 | KCP180 | |

| Iya aiki (kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 | |

| Amfanin makamashi (kWh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

| Compactor | Ƙara (L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Ƙarfin Mota (kw) | 37-45 | 55-75 | 75-90 | 90-132 | 132-160 | 160-185 | |

| Extruder | Diamita Maɗaukaki (mm) | φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Motoci (kw) | 55-75 | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Tace(zabuka) | Nau'in farantin matsayi biyu | ● | ● | ● | ● | ● | ● |

| Nau'in fistan matsayi biyu | ○ | ○ | ○ | ○ | ○ | ○ | |

| Nau'in fistan mai ja da baya | ○ | ○ | ○ | ○ | ○ | ○ | |

| Nau'in tsaftace kai ta atomatik | ○ | ○ | ○ | ○ | ○ | ○ | |

| 2nd Extruder (na zaɓi) | Diamita Maɗaukaki (mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Motoci (kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-160 | |

| A ƙasa (zaɓuɓɓuka) | Ruwan zobe pelletizer | ● | ● | ● | ● | ● | ● |

| Strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Pelletizer na madauri ta atomatik | ○ | ○ | ○ | ○ | ○ | ○ | |

| Pelletizer na karkashin ruwa | ○ | ○ | ○ | ○ | ○ | ○ | |

● misali ○ madadin